Innovative PCB Design Enhances Brewery Control Systems

Shenzhen, Friday, 1 November 2024.

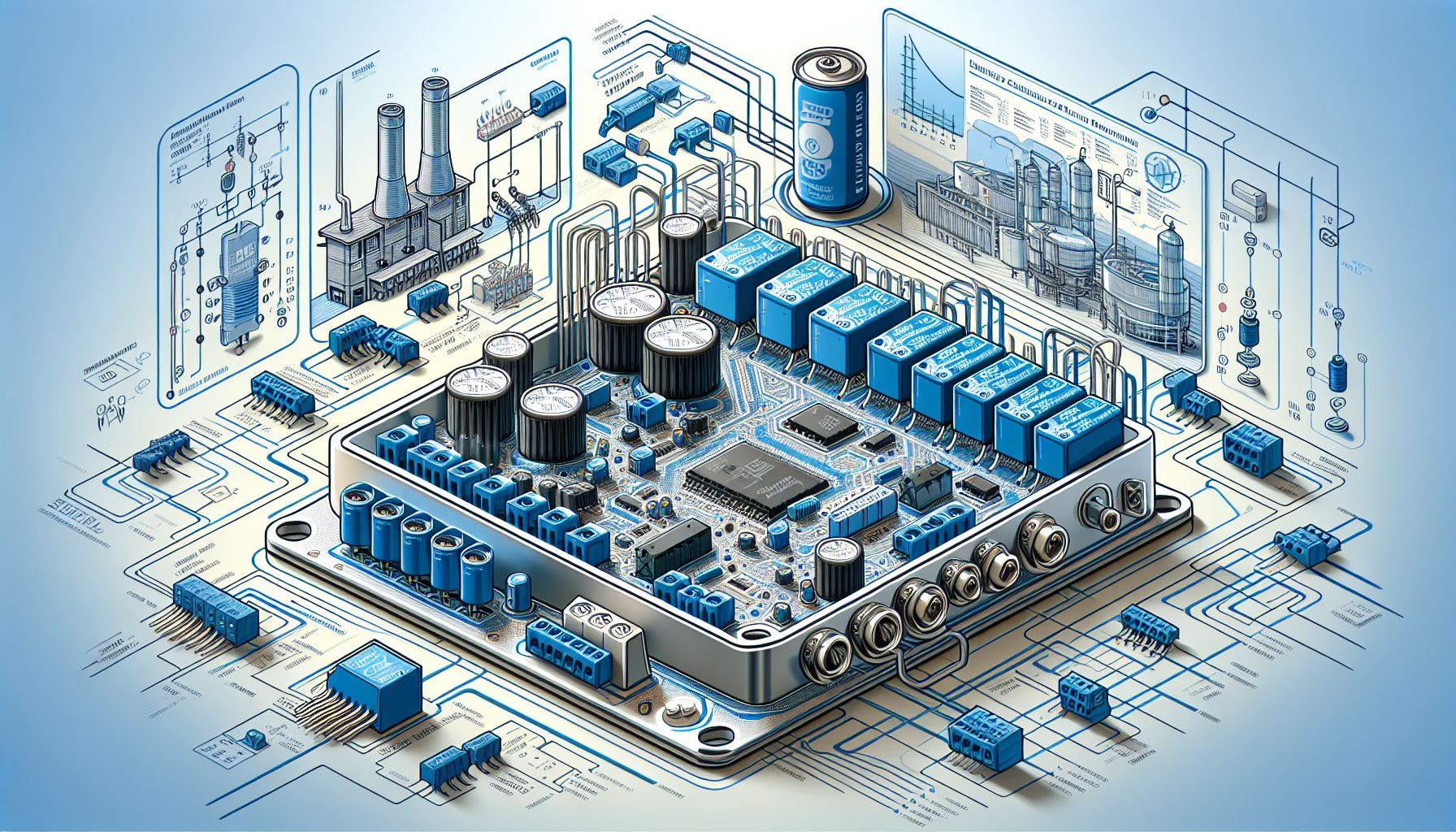

A new PCB design for brewery controllers optimizes the integration of solid-state relays (SSRs) using slim relay DIN bases. This cost-effective solution streamlines mains voltage management, sourcing components from AliExpress to create a more efficient and compact control system for brewing operations.

Streamlining Brewery Operations

In the dynamic world of brewing, efficiency and precision are key. The newly designed PCB for brewery controllers addresses these needs by integrating solid-state relays (SSRs) through slim relay DIN bases. This innovation allows for effective management of mains voltage, critical for the automation of brewing processes. By sourcing components from cost-effective outlets, such as AliExpress, the design not only enhances performance but also reduces overall costs for brewers.

Technical Design and Components

At the heart of this design is a simple yet effective PCB layout. The board serves as a hub for connecting various components, including screw terminals and RJ connectors, allowing for easy integration of external devices. The slim relay DIN bases facilitate the plug-in of 6A, 240VAC SSRs, optimized for control voltages starting at 3V. This setup is particularly beneficial for handling high power loads without the bulk of traditional relays, ensuring a compact and tidy installation.

Advanced Features and Integration

This PCB design is complemented by a touchscreen power controller, which offers a user-friendly interface for managing the brewing process. The controller is housed in a splash-proof enclosure and includes a sensor port and multiple power cords for pumps and chillers. Recent updates have improved the integration of SSRs, enhancing power management capabilities. Additionally, the controller’s Wi-Fi module supports both iOS and Android, allowing for remote monitoring and adjustments, although critical functions are safeguarded with limited remote access for safety.

Optimizing for Future Growth

As the brewing industry continues to grow, the demand for efficient and scalable solutions becomes increasingly important. This PCB design not only addresses current operational needs but also positions breweries to scale their operations with minimal additional investment. By leveraging modern technology and affordable components, breweries can ensure they remain competitive and responsive to market demands. The integration of SSRs, in particular, provides a robust foundation for future enhancements in automation and process control.