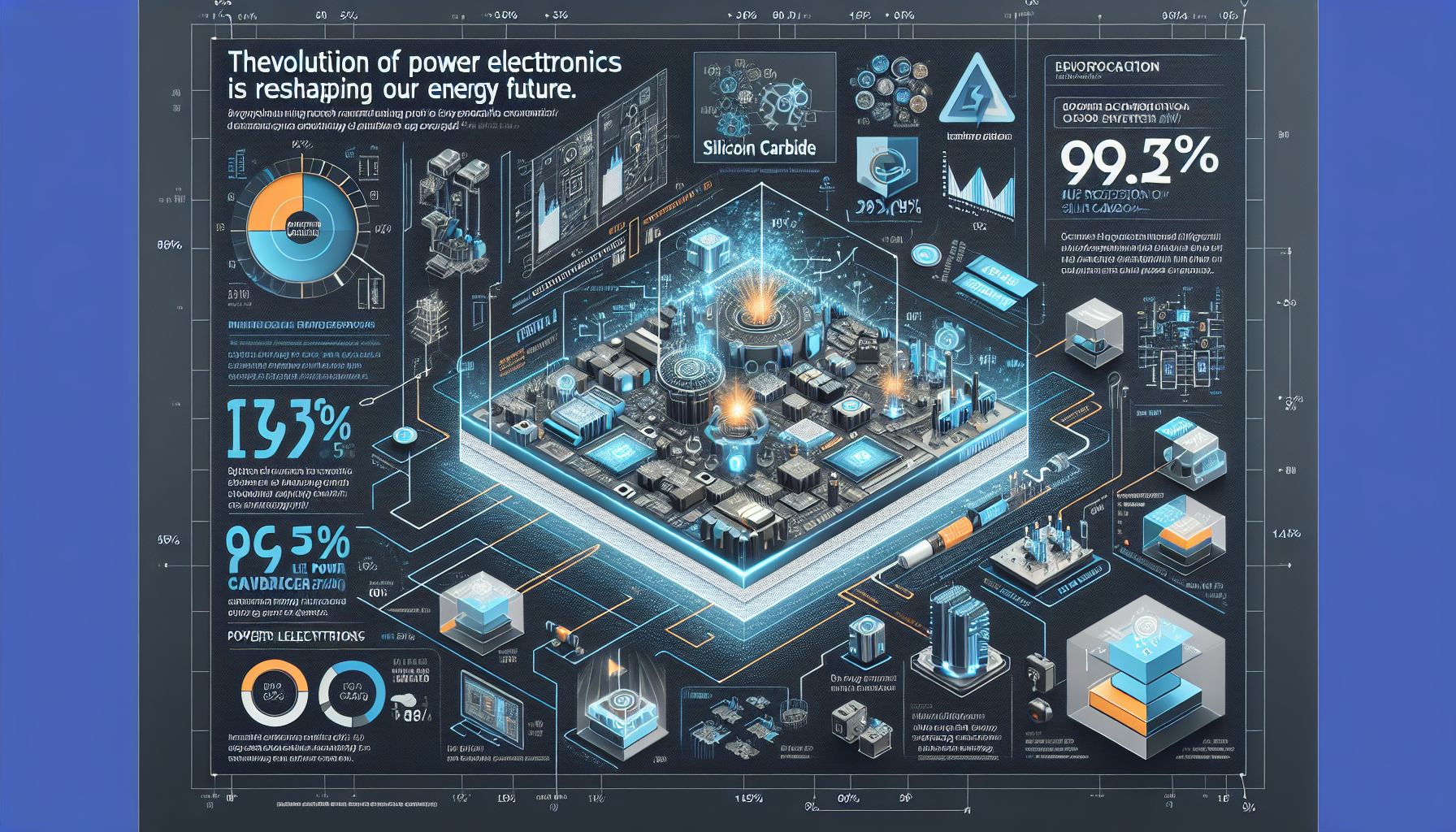

Power Electronics Revolution: How Silicon Carbide is Reshaping Our Energy Future

Global, Friday, 29 November 2024.

The power electronics industry is witnessing a transformative surge, driven by a projected 19.3% growth in SiC (Silicon Carbide) technology through 2030. This breakthrough material is revolutionizing electric vehicles and renewable energy systems, offering unprecedented efficiency levels up to 99.5% in power conversion. As global markets, particularly in Asia Pacific, embrace this technology, it’s not just about better performance – it’s about reshaping how we manage and distribute energy in our increasingly electrified world.

Silicon Carbide: A Game Changer in Power Electronics

Silicon Carbide (SiC) has emerged as a pivotal material in the power electronics sector, offering numerous advantages over traditional silicon. Its superior thermal conductivity and high voltage resistance make it ideal for applications demanding high efficiency and reliability, such as electric vehicles (EVs) and renewable energy systems. The global SiC ingots market is expected to grow at a compound annual growth rate (CAGR) of 19.3% from 2025 to 2030, highlighting the increasing demand for SiC-based components[1]. These advancements are not only enhancing the performance of power electronics but also contributing to significant energy savings and reduced carbon footprints.

Impact on Electric Vehicles and Renewable Energy

The adoption of SiC technology is particularly transformative for the electric vehicle industry. High voltages and currents are a norm in EVs, and SiC’s ability to efficiently manage these parameters helps in reducing power losses and extending vehicle range. Additionally, SiC-based components are vital in developing fast-charging systems, addressing one of the major concerns of EV users—charging time[1]. In renewable energy, SiC’s role is equally crucial. Power electronics are integral to managing energy conversion and distribution in systems like solar and wind, where SiC’s efficiency can lead to better energy yield and grid compatibility.

Technological Advancements and Market Dynamics

The SiC market is witnessing rapid technological advancements, including larger diameter ingots and improved crystal growth techniques, which enhance device performance and adoption[1]. Key regions such as Asia Pacific are leading the charge, with countries like China, Japan, and South Korea at the forefront due to their robust electronics industries and increasing focus on energy-efficient solutions. The electronics segment holds approximately 60% of the market share of SiC ingots as of 2023, driven by the demand for high-performance semiconductors in EVs and renewable energy systems[1].

Future Prospects and Challenges

Looking ahead, the integration of SiC in power electronics is expected to expand further with advancements in semiconductor technology and greater integration with AI and IoT devices. These developments will likely open up new applications in smart grids and next-generation electric vehicles[2]. However, challenges remain in managing high currents and voltages to minimize power losses, alongside ensuring reliability and safety. Despite these hurdles, the potential benefits of SiC are poised to drive its adoption across various sectors, reshaping the energy landscape for a more sustainable future.