ESP32-Powered Wire EDM Machine: DIY Precision Electronics

Global, Sunday, 3 November 2024.

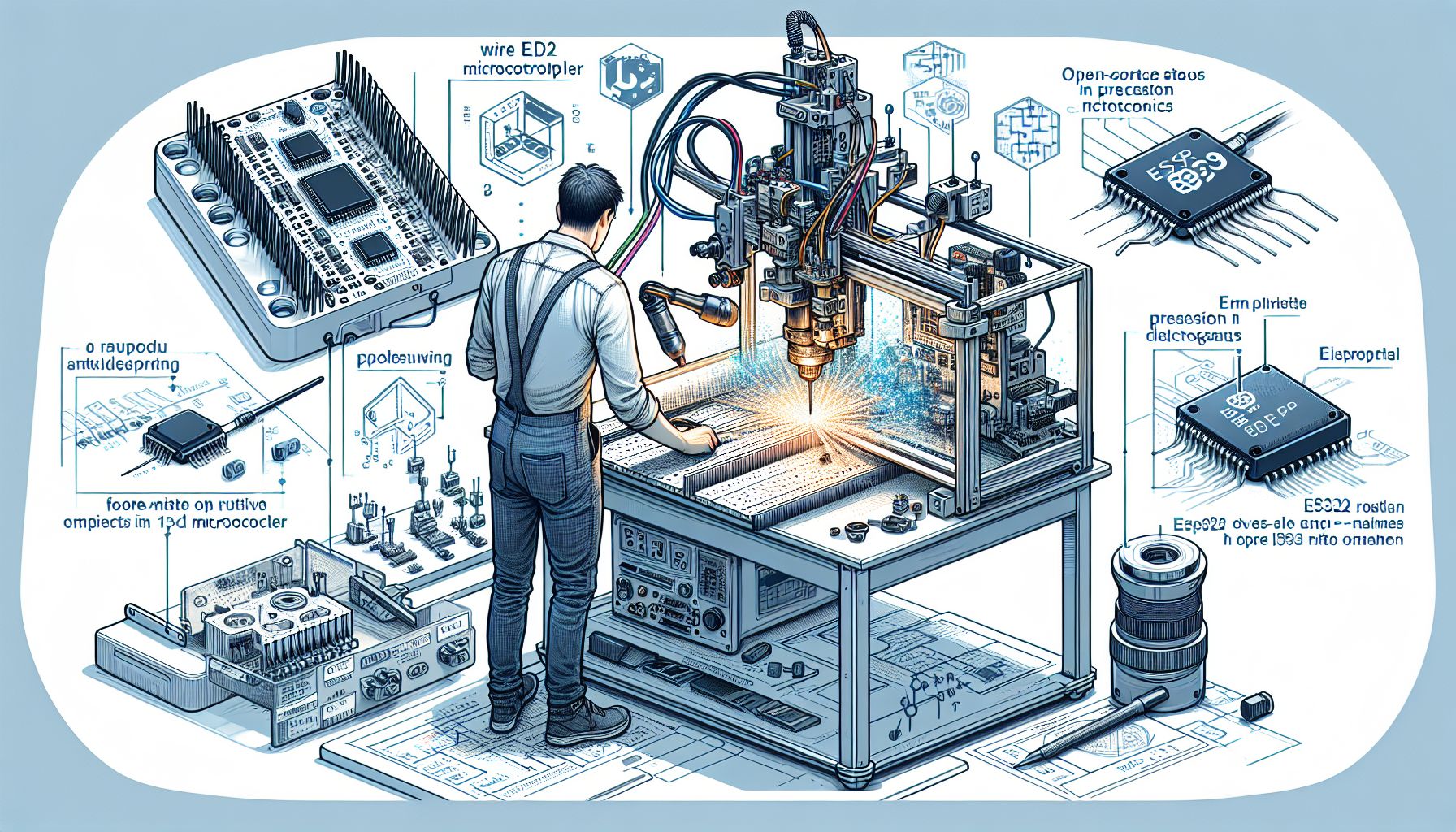

An innovative hobbyist creates a Wire EDM machine using an ESP32 microcontroller, showcasing the potential of open-source tools in DIY automation. This project demonstrates how versatile microcontrollers can advance precision electronics for enthusiasts.

Introduction to Wire EDM and ESP32

Wire Electrical Discharge Machining (EDM) is a process that uses electrical discharges to shape metal materials with precision. Traditionally, this technology has been confined to industrial applications due to its complexity and cost. However, the introduction of the ESP32 microcontroller into the DIY arena is changing this landscape. The ESP32, known for its power and versatility, is an open-source microcontroller platform that hobbyists are increasingly leveraging to create sophisticated electronic projects. By harnessing the capabilities of the ESP32, hobbyists can now explore the possibilities of Wire EDM in their own workshops.

Designing the Wire EDM Machine

The design of a Wire EDM machine powered by an ESP32 involves several key components, each playing a crucial role in the machine’s operation. The core of the setup includes the ESP32 microcontroller, which acts as the brain of the operation, controlling the wire’s movement and the electrical discharges. Other essential components include a precision stepper motor for wire positioning, a high-frequency pulse generator, and a conductive wire, typically made of brass or copper, which acts as the cutting tool. The careful integration of these components ensures that the machine operates smoothly and efficiently, capable of producing intricate metal designs.

Circuit Design and Software Implementation

The circuit design for this project revolves around the ESP32’s ability to handle complex tasks with minimal latency. The microcontroller is connected to a motor driver circuit that controls the stepper motor, while another circuit manages the pulse generation necessary for the EDM process. The software, typically written in C++ or Python, is uploaded to the ESP32 using an Integrated Development Environment (IDE) compatible with the microcontroller. This software is responsible for translating design inputs into precise motor movements and discharge sequences, allowing for detailed and accurate metal shaping.

Applications and Impacts of DIY Wire EDM

The creation of a Wire EDM machine using an ESP32 microcontroller opens up numerous possibilities for DIY enthusiasts. This setup allows for the fabrication of complex metal parts that would otherwise be difficult or expensive to produce. As a result, hobbyists can undertake projects involving custom metal components, such as gears, intricate sculptures, or electronic casings, with a level of precision previously unattainable in a home setting. Furthermore, the use of open-source tools and components democratizes access to advanced manufacturing techniques, fostering innovation and creativity within the DIY community.