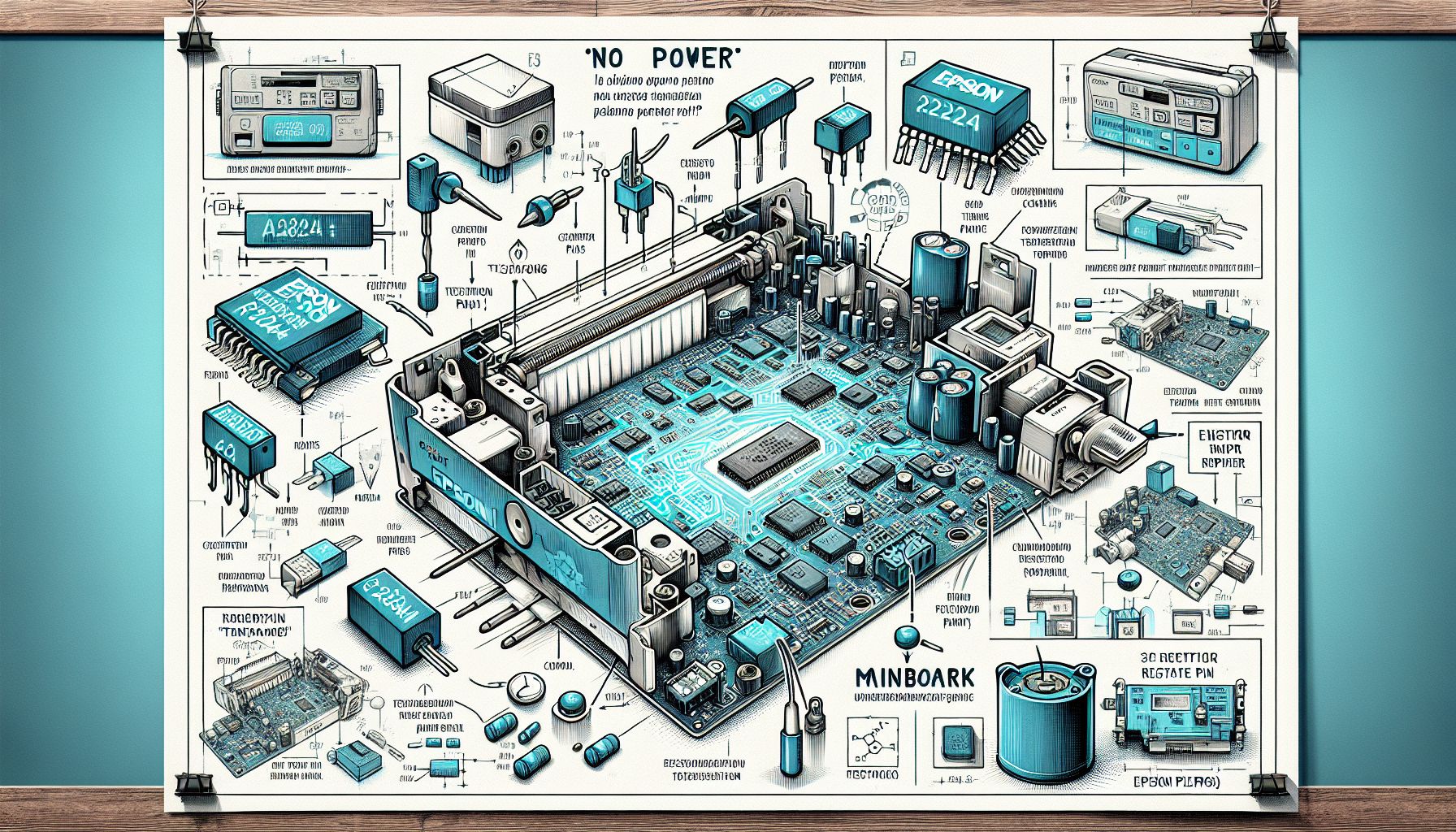

Resolving 'No Power' Issues in Epson EcoTank Printers with Transistor Repairs

Global, Sunday, 8 December 2024.

Learn how to fix ‘no power’ issues in Epson EcoTank printers by repairing the mainboard with transistor pairs A2222 and C6144, bypassing typical power supply problems.

Understanding the Root Cause

When Epson EcoTank printers display ‘no power’ symptoms, the issue isn’t always related to the power supply unit. According to recent technical analyses, a blown-out mainboard (also known as motherboard or formatter board) is often the culprit [1]. This problem can be effectively resolved by replacing specific transistor pairs on the mainboard, particularly the A2222 (2SA2222) and C6144 (2SC6144) transistors [1].

Technical Specifications and Components

The recommended transistor pairs feature impressive technical specifications, including large current capacity of IC=-10A and high-speed switching capabilities with tf=22ns(typ) [1]. These components utilize MBIT process technology and maintain a low collector-to-emitter saturation voltage of VCE(sat)=-250mV(typ) [1]. For different printer models like the L1800 and 1390 series, alternative transistor combinations such as the A2210/C6082 pair may be required [5].

Market Availability and Support

As of December 2024, these repair components are readily available through various specialized electronics suppliers. Recent market data shows that repair kits are being actively distributed across 149 countries, with positive customer feedback regarding their effectiveness [2]. Some suppliers, as observed in current marketplace listings, maintain limited stock with only 5 units available for certain transistor sets [4].

Professional Insights and Recommendations

While mainboard repairs traditionally required professional intervention, recent developments have made DIY repairs more accessible to experienced users [1]. For newer printer models experiencing power issues, experts recommend first examining the four transistors on the power bridge (identified by silver heat sinks) before proceeding with replacement [2]. This systematic approach has proven successful in resolving power-related issues across various EcoTank models [1][2].