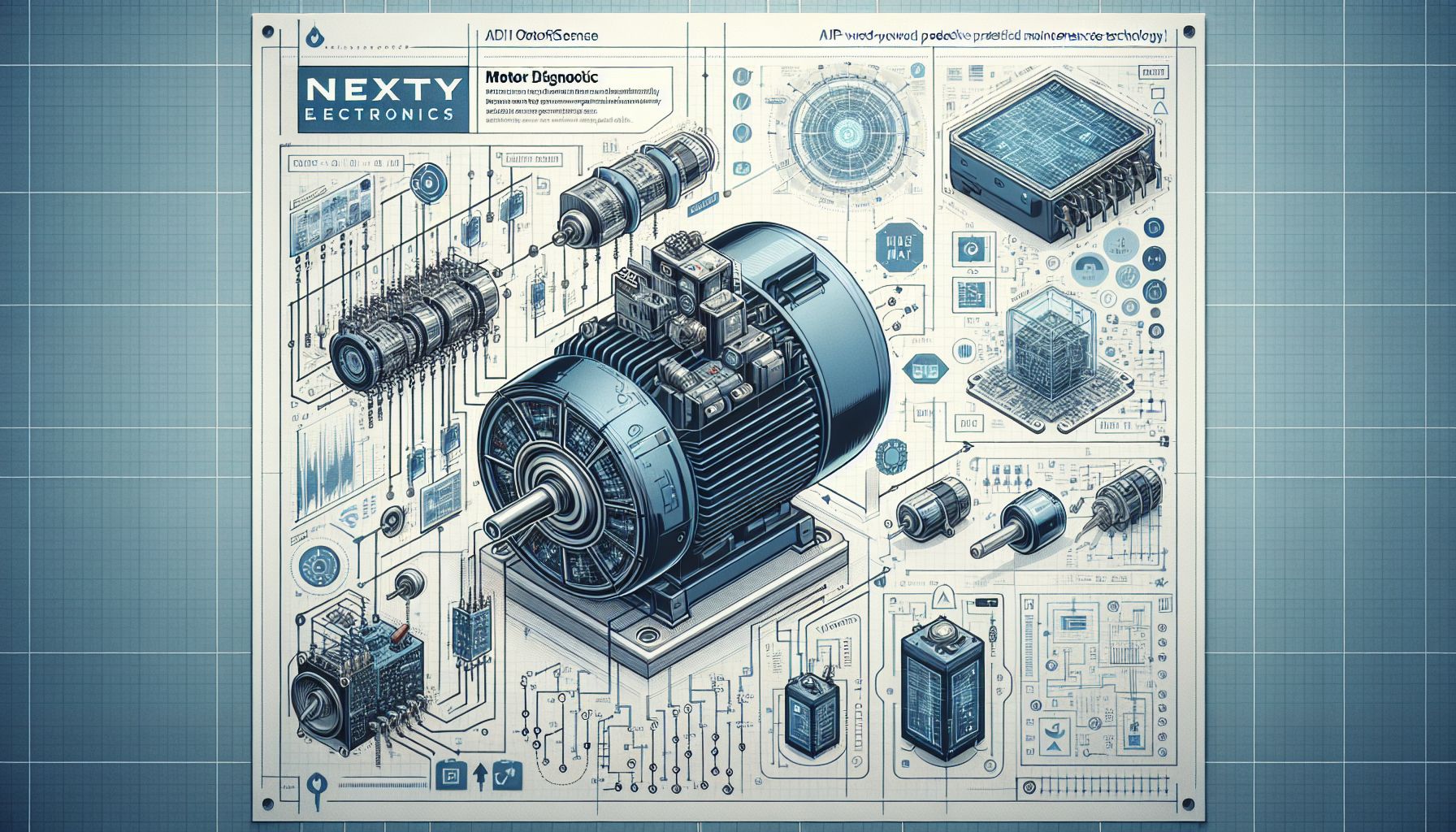

Nexty Electronics Unveils AI-Powered Motor Diagnostic Technology

Berlin, Friday, 11 July 2025.

Nexty Electronics introduces AI-driven predictive maintenance technology, ADI OtoSense, enhancing motor reliability. This smart solution minimizes industrial downtime and costs by predicting failures before they occur.

Revolutionizing Predictive Maintenance with AI

Nexty Electronics, partnering with Analog Devices, has launched the ADI OtoSense Smart Motor Sensor (SMS), a groundbreaking predictive maintenance technology for motors using artificial intelligence and machine learning. By anticipating motor failures beforehand, this innovation transforms industrial operations by reducing unexpected downtimes and cutting maintenance costs by at least 20% [1].

Cutting-edge Features of the ADI OtoSense SMS

The SMS can be installed in just 15 minutes and operates with remarkable efficiency by monitoring nine key areas of a motor 24/7, detecting both electrical and mechanical anomalies without the need for physical electrical connections. This system is suitable for 3-phase induction squirrel-cage motors with a frame size of up to 450 (IEC 60034) or 500 (NEMA MG1), and manages an output range of 0.37 kW–500 kW [2].

Applications and Industrial Impact

This AI-driven technology caters to a wide range of industries, including food and beverage, automotive, and pulp manufacturing. Its integration promises enhanced reliability and efficiency, allowing European manufacturers to meet the rising demand for smart automation. The SMS’s ability to provide real-time data and reduce human inspection enhances operational efficiency, informs maintenance scheduling, and ultimately extends equipment life [1][3].

Contributions to the Fourth Industrial Revolution

The introduction of the ADI OtoSense Smart Motor Sensor aligns with the broader trend of utilizing industrial analytics in the ‘fourth industrial revolution,’ characterized by data-driven decisions. By harnessing IoT sensors and machine learning, predictive maintenance tools like the SMS optimize maintenance operations, saving industries potentially up to $50 billion annually in avoiding unplanned downtime [3][4].