DIY Electronics Breakthrough: Simple Plastic Extruder Enhances PCB Efficiency

Global, Saturday, 16 November 2024.

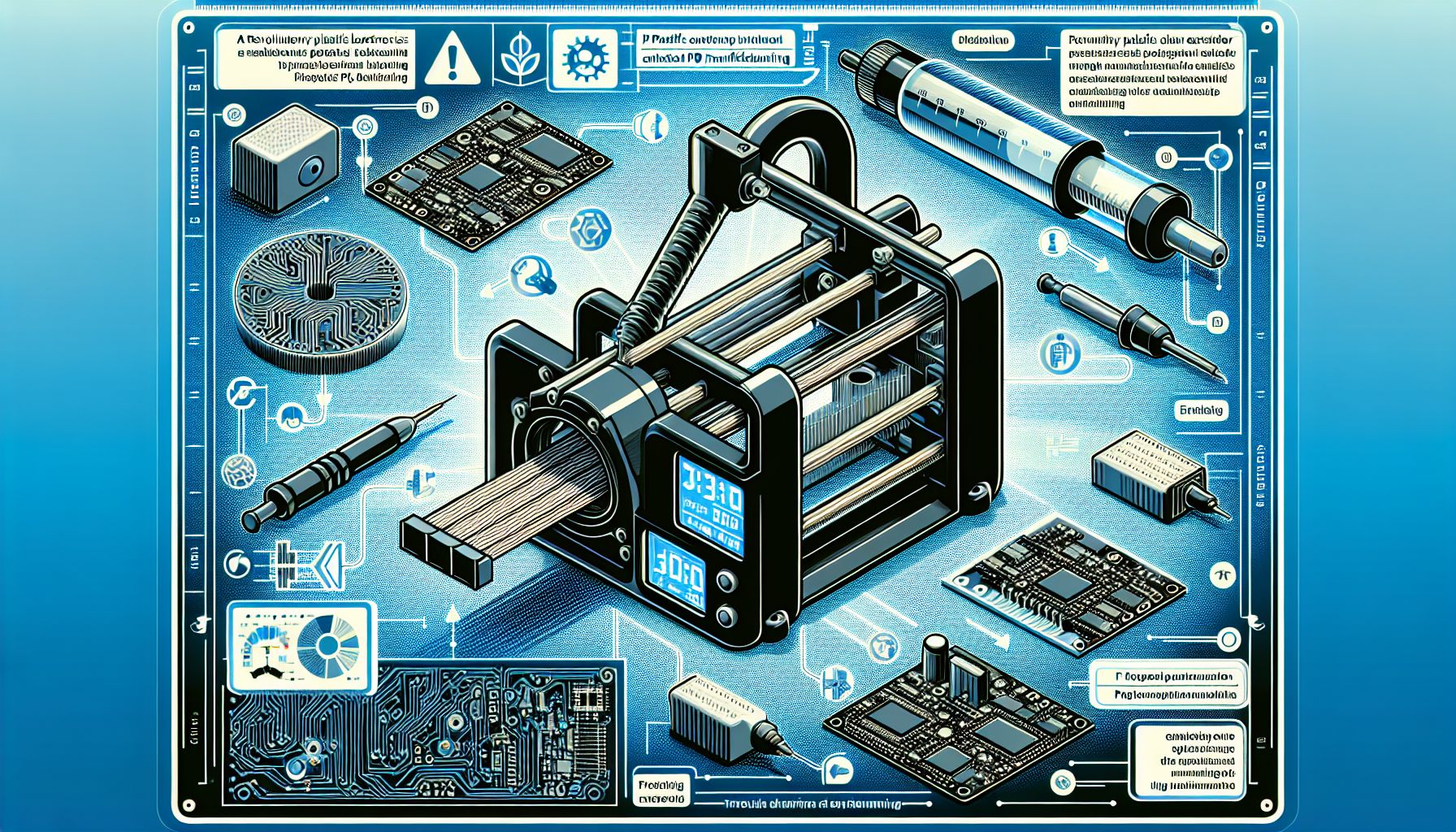

A new simple plastic extruder for DIY electronics enthusiasts promises to revolutionize PCB manufacturing. This innovative device offers improved control and efficiency for hobbyists and professionals, potentially transforming personal circuit board production.

The Need for Enhanced Control in DIY PCB Manufacturing

In the realm of DIY electronics, enthusiasts and professionals alike have long sought methods to refine and streamline the manufacturing of printed circuit boards (PCBs). Traditionally, the production of PCBs involves intricate processes that require precision and significant resources. The introduction of a simple plastic extruder tailored for the DIY community addresses these challenges by offering enhanced control over the manufacturing process. This device allows users to manipulate key components such as the hotend, stepper motor, and fans with intuitive knobs, thus providing a level of customization that was previously difficult to achieve[1].

Technical Specifications and Benefits

The extruder’s design, which integrates easily adjustable controls, marks a significant advancement in DIY electronics. Users can now fine-tune the extrusion process to match specific project requirements, thereby achieving higher precision in PCB production. This flexibility is particularly beneficial when working with various materials, such as glass fiber nylon, which offers higher mechanical strength and heat resistance compared to standard nylon, making it ideal for functional testing and robust applications[5]. The ability to control the extrusion parameters directly translates to more efficient and accurate production runs, minimizing waste and maximizing productivity.

Implications for the DIY Electronics Community

The availability of such an extruder is expected to democratize the process of PCB fabrication, making it more accessible and less costly for individual creators and small-scale manufacturers. By reducing dependency on commercial PCB fabrication services, hobbyists can experiment more freely, accelerating innovation and creativity within the community. Furthermore, the integration of such tools into existing 3D printing setups, like those offered by companies such as Bambu Lab, which push the boundaries of digital and physical creation, further enhances the capabilities of personal manufacturing workspaces[2].

Future Outlook and Potential Developments

Looking ahead, the development of the simple plastic extruder could pave the way for more sophisticated DIY manufacturing solutions. As technologies advance and become more affordable, the potential for integrating additional functionalities, such as automated calibration and multi-material processing, becomes increasingly feasible. This could further elevate the role of DIY electronics in innovation, fostering a new wave of homegrown technological advancements. The implications of these advancements could extend beyond personal projects, influencing industries that rely on rapid prototyping and custom electronics solutions.