AI-Enhanced Force Sensors: The Future of Automotive Safety

Online, Saturday, 23 November 2024.

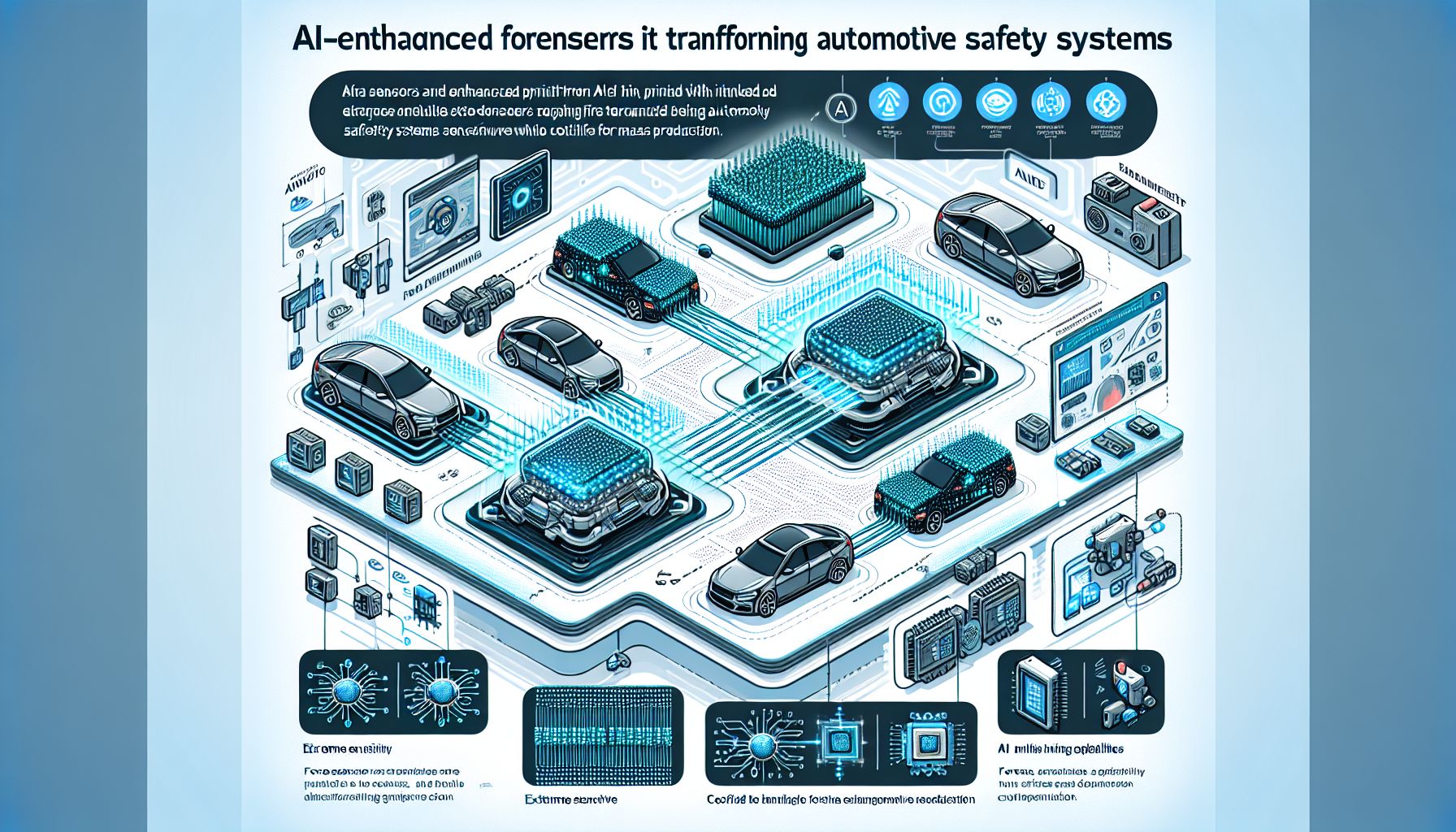

Revolutionary developments in force-sensing technology are transforming automotive safety systems. Interlink Electronics leads innovation with ultra-thin printed sensors that combine AI capabilities for enhanced vehicle collision detection. Their latest sensors, showcasing at electronica 2024 in Munich, demonstrate unprecedented sensitivity while maintaining cost-effectiveness for mass production. This breakthrough represents a significant leap forward in making advanced safety features accessible across the automotive industry.

Innovative Sensor Design: A Closer Look

Interlink Electronics has unveiled its latest advancements in force-sensing technology, which are set to redefine automotive safety standards. By integrating artificial intelligence into their ultra-thin, flexible printed sensors, Interlink is paving the way for more sophisticated vehicle collision detection systems. These sensors, presented at the electronica 2024 in Munich, are designed to deliver high sensitivity and accuracy by leveraging AI’s ability to process complex data patterns efficiently. The integration of AI not only enhances the functionality of these sensors but also enables them to provide real-time feedback, crucial for preventing accidents in dynamic driving conditions.

Comparative Advantages in Automotive Applications

Compared to traditional sensors, Interlink’s printed polymer sensors offer distinct advantages in terms of flexibility and responsiveness. These sensors are capable of functioning as dynamic strain gauges, vibration sensors, and solid-state switches, making them versatile components in the realm of automotive safety. Their lightweight and thin profile allow for seamless integration into vehicle systems without adding significant weight or bulk, a key consideration for electric vehicles aiming to maximize efficiency. Additionally, the cost-effectiveness of these sensors positions them as viable options for widespread adoption across various car models, not just luxury vehicles.

Potential Industrial Applications Beyond Automotive

While automotive applications are at the forefront, the potential uses of Interlink’s AI-enhanced sensors extend far beyond this sector. In the realm of industrial automation, these sensors can be utilized for precise monitoring of machinery, detecting vibrations, and ensuring equipment operates within safe parameters. This capability is particularly beneficial in environments where maintaining constant operational oversight is critical. Furthermore, the healthcare industry stands to benefit from these sensors, where they can be used in medical devices to monitor patient vitals with high precision and reliability, demonstrating their adaptability across multiple sectors.

Future Prospects and Recommendations

Interlink Electronics’ commitment to advancing sensor technology aligns with broader industry trends towards smarter, more connected devices. Looking ahead, continued research and development in materials science could further enhance the durability and sensitivity of these sensors. Incorporating more advanced machine learning algorithms could also improve their decision-making capabilities, making them even more effective in real-time applications. For manufacturers seeking to integrate cutting-edge technology into their products, Interlink’s sensors offer a promising solution that balances performance with cost-efficiency, making them ideal for both high-end and mass-market applications.