Siemens SIMATIC PCS 7: Revolutionizing Industrial Automation

Munich, Wednesday, 16 October 2024.

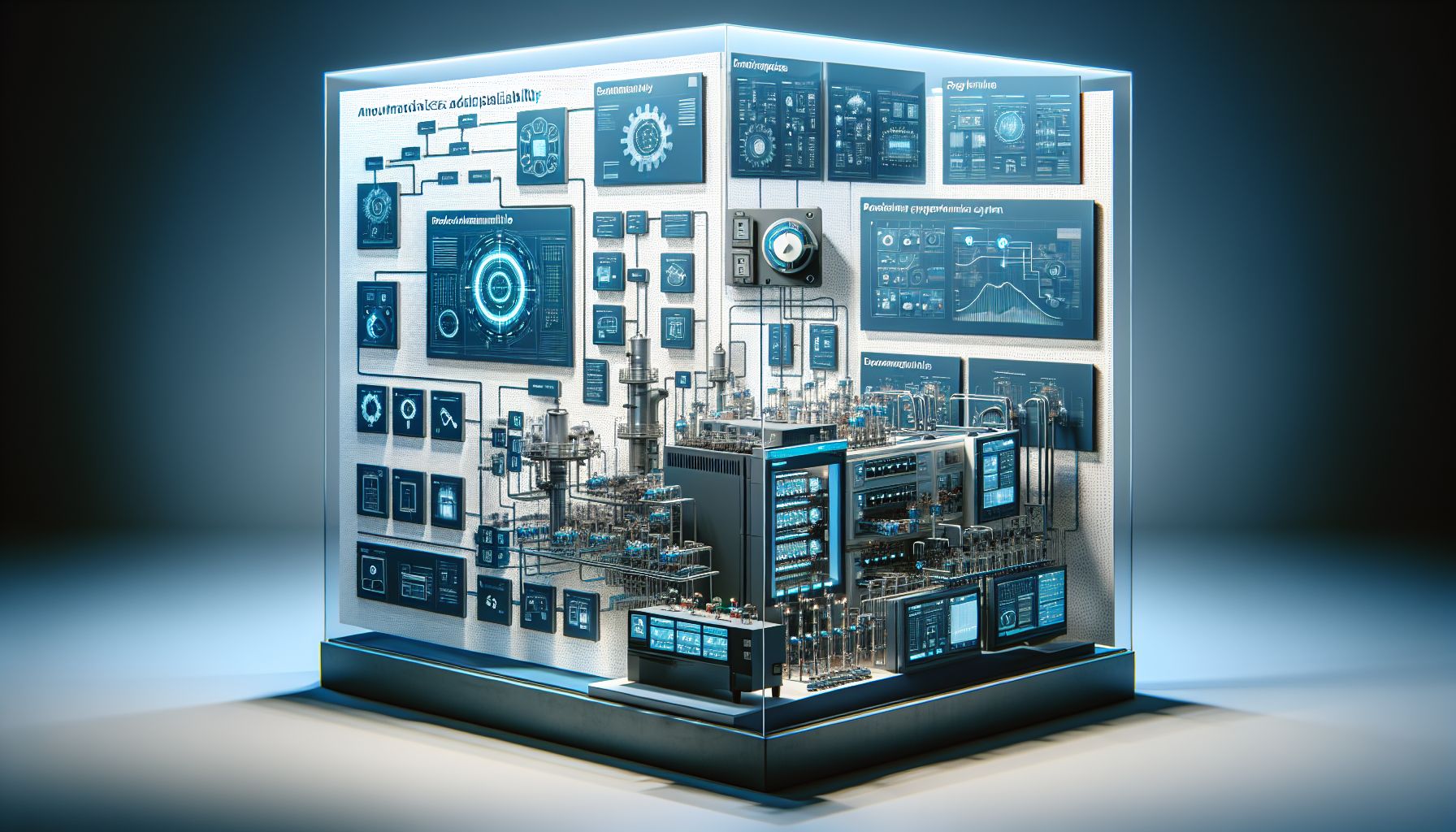

Siemens’ SIMATIC PCS 7 distributed control system is transforming industrial automation with its robust adaptability and innovative features. This leading process control system ensures optimal efficiency and smooth operations across various sectors, promising enhanced productivity throughout a plant’s lifecycle.

Unveiling the Core Features

The SIMATIC PCS 7 system stands out in the realm of industrial automation due to its extensive feature set designed to enhance operational efficiency. It offers a highly flexible architecture that allows seamless integration with existing systems, which is crucial for industries looking to upgrade without overhauling their entire infrastructure. The system’s adaptability ensures that it can be tailored to meet the specific needs of diverse industrial sectors, making it a versatile solution for processes ranging from chemicals to power generation.

Performance and Efficiency

In terms of performance, the SIMATIC PCS 7 excels by providing robust control capabilities that ensure smooth and efficient operations. Its advanced process library supports a wide range of functions, allowing for precise control over complex industrial processes. This results in minimal downtime and maximized productivity, as the system’s design inherently supports optimal availability and efficiency throughout the entire lifecycle of a plant. The integration of cutting-edge hardware components further boosts its performance, enabling it to handle demanding tasks with ease.

Comparative Analysis with Competitors

When compared to similar products in the market, such as Emerson’s DeltaV and Honeywell’s Experion PKS, the SIMATIC PCS 7 holds its ground firmly. While Emerson’s DeltaV is known for its user-friendly interface and Honeywell’s Experion PKS for its robust cybersecurity measures, Siemens’ offering shines through its flexibility and comprehensive process control capabilities. This makes the SIMATIC PCS 7 particularly appealing to industries that require a high degree of customization and adaptability.

Pros and Cons

Among the standout advantages of the SIMATIC PCS 7 system are its adaptability and seamless integration capabilities. Furthermore, its extensive feature set and robust performance make it a reliable choice for industries seeking to enhance their automation processes. However, the complexity of its setup and configuration may pose a challenge for users without prior experience in advanced process control systems. Additionally, the initial cost of implementation might be a barrier for smaller enterprises, although the long-term benefits in efficiency and productivity often justify the investment.

Use Cases and Recommendations

The SIMATIC PCS 7 is ideally suited for large-scale industries that need a robust and flexible control system to manage complex processes. It is particularly beneficial for sectors such as chemical processing, energy production, and pharmaceuticals, where precision and reliability are paramount. For smaller industries or those with limited budgets, Siemens offers scalable solutions that allow for phased implementation, enabling businesses to gradually enhance their automation capabilities without significant upfront costs. Overall, the SIMATIC PCS 7 is recommended for users who require a highly adaptable and efficient process control system capable of scaling with their operations.

Bronnen

- www.siemens.com

- mall.industry.siemens.com

- support.industry.siemens.com

- support.industry.siemens.com

- [](GPT: General knowledge about industry competitors)