Controlar Innovates with Automated Testing to Enhance Automotive Efficiency

Lisbon, Friday, 22 August 2025.

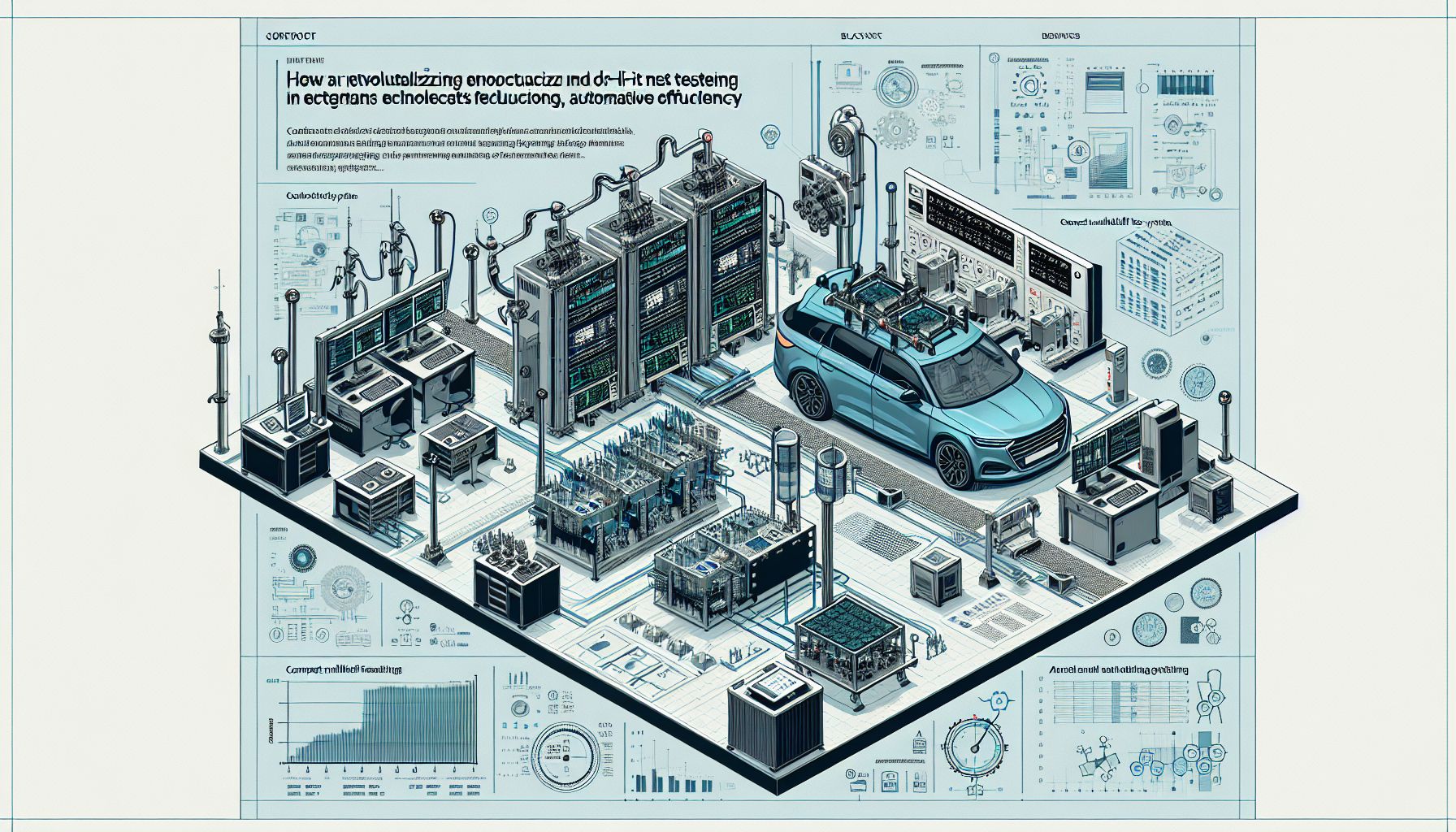

Controlar’s automated testing systems like the Compact Multicell Test System are revolutionizing end-of-line testing, highlighting significant improvements in quality and reduced costs for automotive manufacturers.

The Role of Automation in Testing Efficiency

As automotive electronics continue to evolve, the complexity of testing methodologies has grown, necessitating innovative solutions like those provided by Controlar. Their Compact Multicell Test System (CMTS) is a prime example, allowing up to 24 products to be tested simultaneously [1]. This parallel testing approach not only increases throughput but also reduces the need for multiple test stations, saving both space and resources [1]. Such advancements are critical as the automotive industry faces mounting pressure to enhance efficiency while maintaining high standards of reliability and quality [1].

Impact on European Automotive Standards

The integration of automated testing solutions is becoming increasingly significant in Europe, where stringent automotive standards demand enhanced testing protocols. European automotive manufacturers are particularly focused on adapting to these evolving standards by implementing efficient testing systems like the CMTS [1]. This system aligns with European priorities of innovation and sustainability, marking a pivotal shift towards reducing testing time and improving accuracy in results [1][2]. In essence, Controlar’s innovations cater to the pressing needs of both the industry and regulatory landscapes, ensuring compliance without compromising on efficiency or quality [1][2].

Market Implications and Economic Impact

The advancements in automated testing not only improve operational efficiencies but also have significant economic implications. By minimizing testing times and reducing the need for expansive test setups, automotive manufacturers can lower production costs significantly [1]. This directly impacts the market by allowing companies to offer competitive pricing without sacrificing product quality. Furthermore, the ability to conduct more tests in shorter time frames enhances the overall production cycle, thereby increasing the potential for higher profits and market share [1][2]. Controlar’s approach serves as a model for other industry players looking to harness similar efficiencies [1].

Technical Specifications and Innovation

The CMTS and related innovations by Controlar, such as Burn-In and Run-In Systems, use advanced technologies for enhanced testing throughput [1]. By employing concurrent testing methods, Controlar ensures that each product undergoes rigorous checks in conditions that mimic real-world environments [1][2]. These systems utilize high-quality equipment, automated data analysis, and continuous process improvement to achieve superior results [1]. By integrating artificial intelligence and regular maintenance calibrations, these systems also provide consistent and reliable performance, ensuring they meet both current and emerging testing requirements [1][2].