Surface Mount Resistors: Powering Compact Electronics

Corby, Wednesday, 23 October 2024.

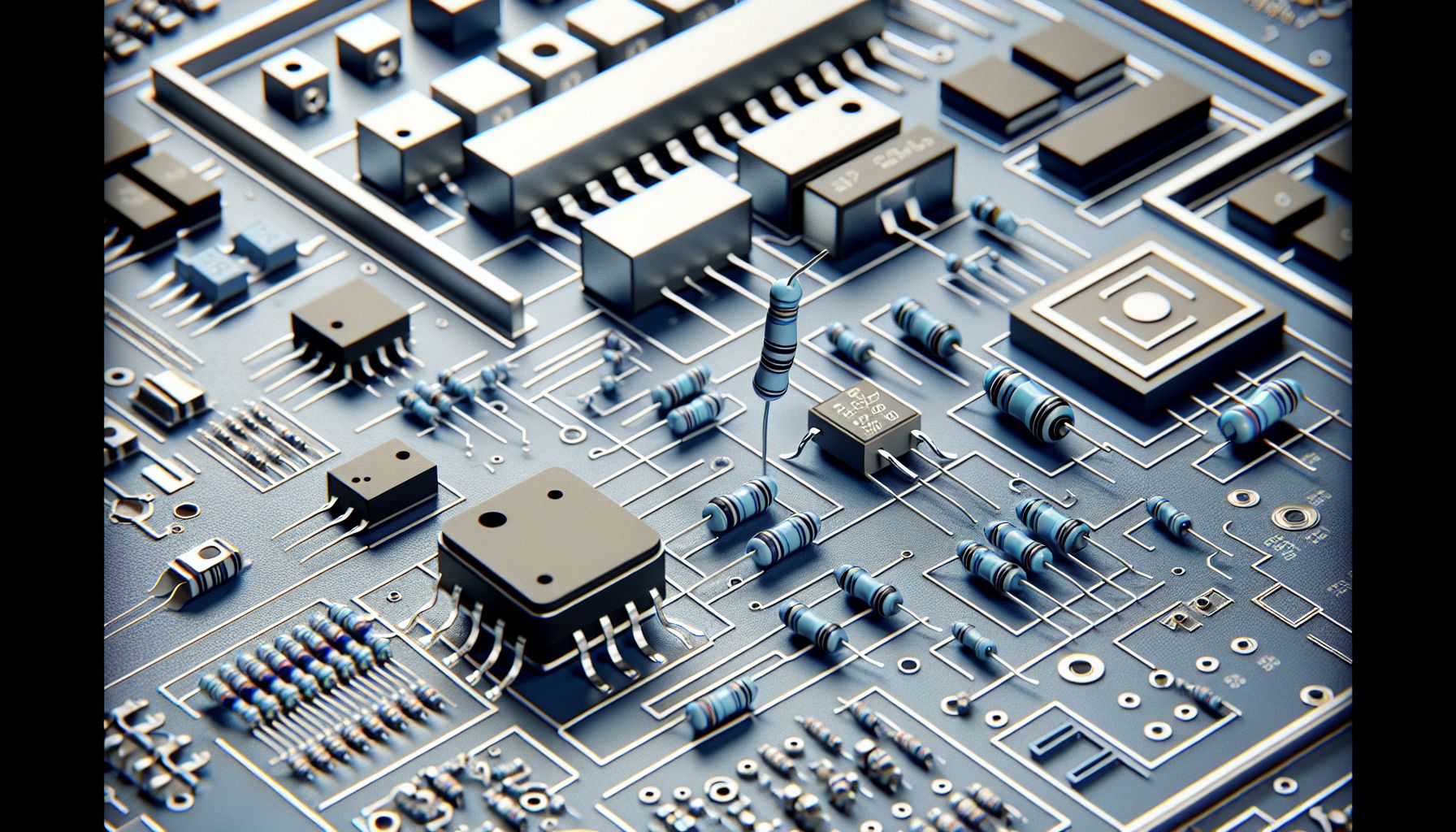

Surface mount resistors are revolutionizing modern electronics by enabling smaller, more efficient devices. These tiny components play a crucial role in controlling current flow, offering space-saving advantages and high reliability across various industries, from telecommunications to automotive.

Overview of Surface Mount Resistors

Surface mount resistors (SMDs) are indispensable in today’s electronics, bridging the gap between traditional components and the need for compact, efficient design. These resistors are soldered directly onto the surface of printed circuit boards (PCBs), allowing for the reduction of circuit board space and enhancing the overall performance of electronic devices. Their ability to control electrical current is akin to how a tap regulates water flow, ensuring precise and reliable operation in various applications.

Types and Applications

There are several types of surface mount resistors, each tailored for specific applications. Thin film resistors offer higher precision, making them suitable for tasks requiring exact measurements, whereas thick film resistors are more economical and used for general purposes. Moulded wirewound resistors are employed where higher power is needed, and foil resistors provide ultra-high precision with low temperature coefficients. These diverse options make SMDs versatile in industries like telecommunications, automotive, and medical equipment, where compact and efficient designs are crucial.

Practical Use Cases

In telecommunications, SMDs enable the miniaturization of mobile devices and infrastructure components, allowing for more features in a smaller footprint. In the automotive industry, especially with AEC Q200 qualified resistors, they contribute to the reliability and efficiency of electronic control units. Medical devices benefit from SMDs’ precision and compactness, which are essential for portable diagnostic and therapeutic equipment. Additionally, personal devices such as smartphones and wearables rely heavily on SMDs to achieve sleek designs without compromising functionality.

Comparison and Recommendations

When selecting surface mount resistors, consider the specific needs of your application. For high-precision tasks, thin film or foil resistors are recommended. For general applications where cost is a concern, thick film resistors are suitable. Melf resistors offer excellent pulse load capability, ideal for circuits experiencing transient loads. As technology continues to advance, the role of SMDs in electronics will only grow, making them a critical component for engineers and designers aiming to create cutting-edge, space-efficient devices.