Innovations in Injection Molding Reshape Consumer Electronics Design

Global, Monday, 21 October 2024.

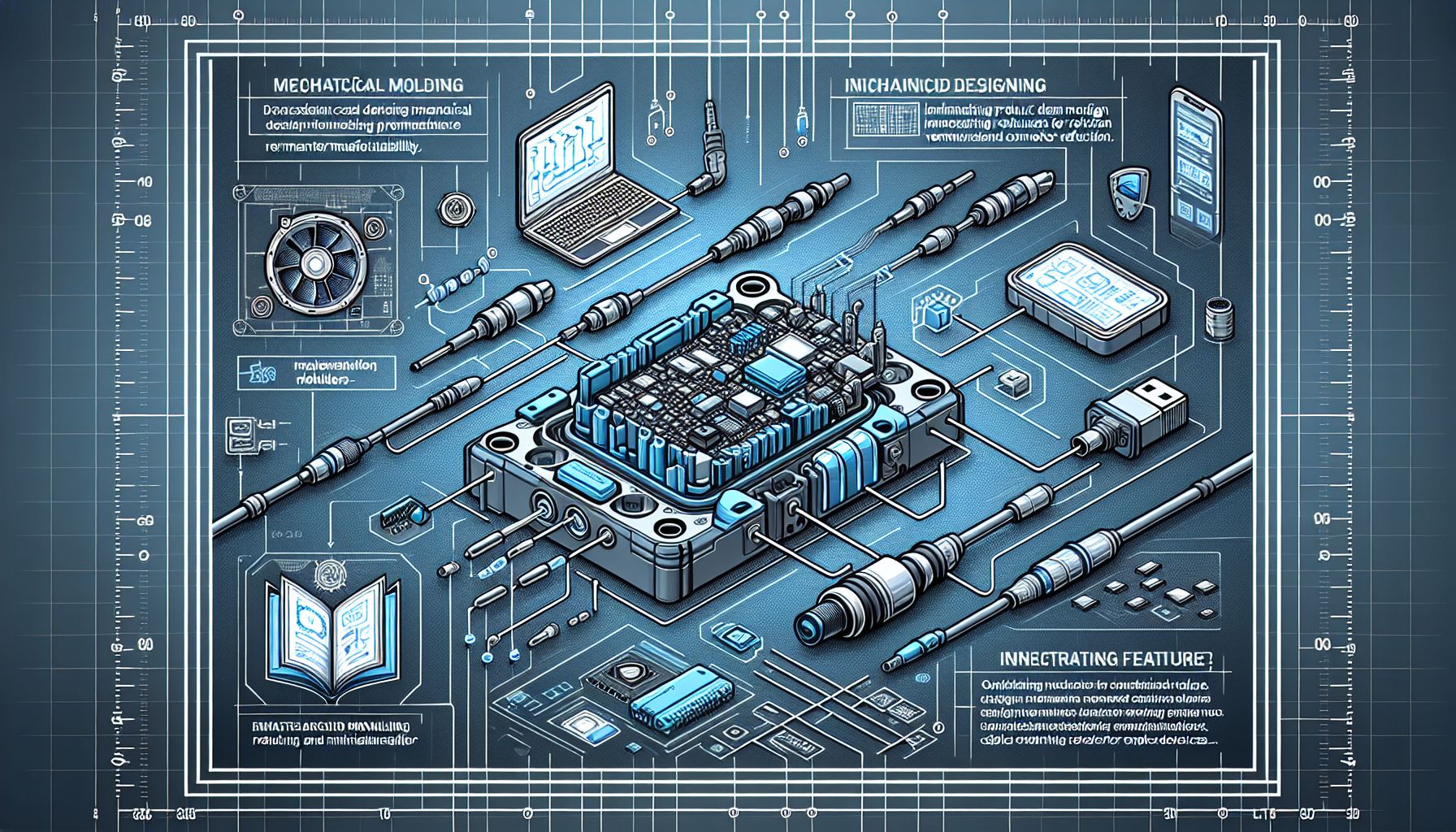

Recent advancements in mechanical design processes for injection molded consumer electronics are enhancing product performance and manufacturability. Engineers are tackling challenges in waterproofing, feature integration, and miniaturization, while optimizing cable routing and connector selection for increasingly complex devices.

Advancements in Injection Molding Techniques

Injection molding, a cornerstone of consumer electronics manufacturing, has seen significant innovations aimed at improving both product performance and manufacturability. Recent developments focus on integrating complex features into compact designs without compromising on durability or functionality. Engineers are increasingly utilizing advanced materials and refined molding techniques to create enclosures that are not only waterproof but also capable of housing intricate electronic components efficiently. This evolution is crucial as consumer expectations drive the demand for sleeker, more feature-rich devices.

Challenges in Design and Connectivity

One of the primary challenges highlighted in the design of injection molded products is the effective integration of electronic components, particularly concerning cable routing and connector selection. As devices become more compact, ensuring that internal wiring is both efficient and secure becomes paramount. Innovative solutions such as the use of heat-serts and cable clips are being explored to enhance connectivity while maintaining the structural integrity of the device. These strategies are essential in ensuring that the products meet high standards of reliability and performance in diverse environmental conditions[1].

Leveraging Software for Enhanced Design

Software tools like Autodesk Fusion are playing a pivotal role in revolutionizing the design process for consumer electronics. By integrating functionalities for 3D modeling, simulation, and electronic design, these tools enable engineers to visualize and iterate on designs rapidly. The use of digital twin technology within these platforms allows for real-world simulations, which help in refining designs to ensure they meet functional standards before physical production begins. This approach not only reduces prototyping costs but also speeds up the development timeline, allowing companies to stay competitive in a fast-paced market[2].

Future Outlook and Recommendations

As the consumer electronics industry continues to evolve, the role of mechanical design in product development cannot be overstated. Engineers are encouraged to adopt a holistic approach that considers both the mechanical and electronic aspects of product design. Utilizing advanced software tools, such as Autodesk Fusion, and staying abreast of industry trends will be crucial for developing products that not only meet current market demands but also anticipate future needs. For recent graduates and seasoned professionals alike, a focus on continuous learning and adaptation to new technologies will be key to success in this dynamic field.