AI and Smart Sensors Revolutionize Industrial Filtration

Berlin, Monday, 30 June 2025.

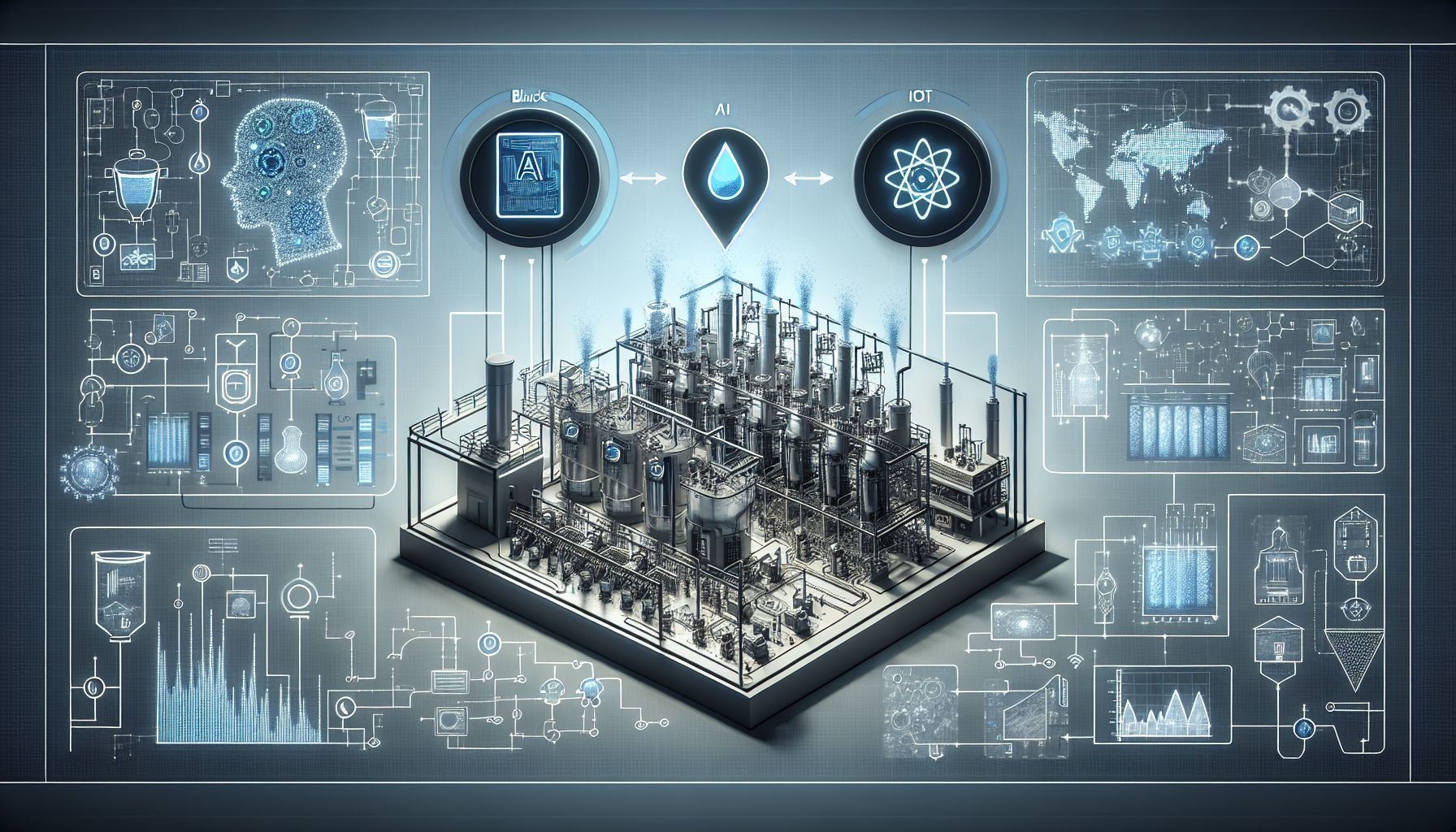

Recent advancements in industrial filtration now leverage AI and IoT to enhance efficiency, ensuring compliance with strict regulations and optimizing performance in diverse sectors.

Integration of AI and IoT in Filtration Systems

The integration of artificial intelligence (AI) and the Internet of Things (IoT) into industrial filtration systems represents a significant leap in technological advancement. These smart filtration systems are equipped with capabilities for real-time monitoring and performance optimization, largely facilitated by AI’s ability to provide predictive maintenance solutions. This not only reduces downtime but also enhances the overall efficiency of filtration processes [1]. IoT-enabled smart sensors play a crucial role by continuously collecting data on various parameters such as pressure, flow rate, and contamination levels. These sensors allow for immediate remedial actions, thus minimizing potential environmental harm [1].

Transformative Impact and Economic Benefits

The adoption of smart technologies in industrial filtration is proving transformative across various sectors. By automating data collection and analysis, firms can make more informed, data-driven decisions that improve their operational agility and compliance with stringent environmental regulations. The transition to smart systems has notably decreased operational costs by improving precision and automating previously manual monitoring tasks [1][5]. Additionally, these technologies facilitate remote management of filtration systems through cloud connectivity, saving both time and resources for organizations with geographically dispersed operations [1].

Technical Specifications and Integration

Advanced filtration systems leveraging smart sensors and AI are defined by high responsiveness and minimal programming requirements. For instance, Smart VS sensors can be deployed swiftly and configured through simple interfaces without the need for complex programming, making them accessible to a broader range of industries [2]. These sensors can detect anomalies through AI, monitoring deviations in real-time to maintain optimal operational conditions [2]. Furthermore, the seamless integration of these intelligent systems with existing industrial infrastructure is achievable without significant changes or additional costs, a principle echoed by advancements in sensor technology that aim to reduce installation complications [3][5].

Challenges and Future Prospects

While the integration of AI and IoT in industrial filtration offers numerous advantages, challenges persist. Initial costs for smart system deployments remain high, and concerns about data security continue to be significant barriers to widespread adoption [5][7]. Furthermore, the lack of standardization can complicate integration and interoperability of these technologies within existing control systems. However, the potential cost savings and operational efficiencies these systems offer suggest a positive outlook for further adoption in sectors mandated to follow strict regulatory compliance and sustainability goals [7].